Posted by Admin on 04-08-2023 in Shiksha hub

DCS Introduction, Admission, Registration, Eligibility, Duration, Fees, Syllabus 2024

Introduction about DCS

In the fast-paced world of industrial automation, Distributed Control Systems (DCS) have emerged as the backbone of efficient and streamlined operations. These systems play a pivotal role in overseeing and controlling complex processes across various industries, ensuring seamless functionality and optimal performance.

Definition of DCS

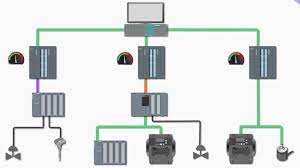

Distributed Control Systems, commonly known as DCS, refer to a centralized system that monitors and manages a network of interconnected control loops. Unlike traditional control systems, DCS involves the distribution of control functions across multiple subsystems, allowing for more flexibility and scalability.

Importance of DCS in modern industries

In the dynamic landscape of modern industries, the significance of DCS cannot be overstated. These systems provide a holistic approach to process control, offering real-time monitoring, efficient decision-making, and improved overall performance.

Evolution of DCS

Historical background

The evolution of DCS dates back to the mid-20th century when industries began seeking more advanced methods to control complex processes. The shift from centralized to distributed control marked a revolutionary change in the automation landscape.

Key milestones in DCS development

Over the years, DCS has undergone significant transformations. Key milestones include the integration of digital technologies, the development of advanced communication protocols, and the evolution of user-friendly interfaces.

Components of DCS

Centralized control

Centralized control is a core component of DCS, allowing operators to monitor and manage various processes from a central location. This centralized approach enhances efficiency and ensures a synchronized operation of different elements within the system.

Remote terminal units

DCS incorporates remote terminal units (RTUs) that act as communication bridges between the central control system and field devices. These units enable the seamless exchange of data, contributing to the overall responsiveness of the system.

Communication protocols

The use of standardized communication protocols is crucial for the successful functioning of DCS. These protocols facilitate the exchange of information between different components, ensuring a smooth flow of data and commands.

Advantages of DCS

Improved process efficiency

DCS enhances process efficiency by providing a comprehensive overview of the entire system. This enables operators to make informed decisions promptly, optimizing resource utilization and minimizing downtime.

Enhanced safety measures

The real-time monitoring capabilities of DCS contribute to enhanced safety measures in industrial settings. Rapid identification and response to potential issues mitigate risks and ensure a secure working environment.

Real-time monitoring capabilities

One of the key advantages of DCS is its ability to provide real-time monitoring of processes. This feature allows operators to identify anomalies promptly and implement corrective actions, minimizing the impact on operations.

Applications of DCS

Manufacturing sector

DCS finds extensive applications in the manufacturing sector, where intricate processes require precise control. The ability to monitor and regulate various aspects of production contributes to increased productivity and quality.

Energy management

In the realm of energy management, DCS plays a vital role in optimizing the performance of power plants. The system ensures efficient energy distribution, reducing waste and promoting sustainability.

Chemical and petrochemical industries

The chemical and petrochemical industries rely heavily on DCS for the control of complex manufacturing processes. The precision and scalability offered by DCS contribute to the safe and efficient production of chemicals.

Challenges and Solutions

Cybersecurity concerns

As with any advanced technology, DCS is not immune to cybersecurity threats. Addressing these concerns requires robust security measures, including regular updates, encryption, and employee training.

System integration challenges

The integration of DCS with existing systems can pose challenges. However, careful planning, thorough testing, and collaboration with experienced professionals can overcome these obstacles.

Future developments in DCS technology

The future of DCS holds promise with ongoing research and development. Anticipated advancements include enhanced artificial intelligence integration, improved data analytics, and increased system autonomy.

Case Studies

Successful DCS implementations

Several industries have witnessed notable success with DCS implementations. Case studies highlight improved efficiency, reduced operational costs, and enhanced overall performance.

Impact on industries

The impact of DCS on industries is profound, leading to increased competitiveness, streamlined processes, and a higher level of adaptability to changing market demands.

DCS in the Future

Emerging trends

Future trends in DCS include the adoption of edge computing, greater emphasis on cybersecurity measures, and the integration of Internet of Things (IoT) technologies for more comprehensive control.

Potential advancements

Advancements in DCS technology may include the development of self-optimizing systems, increased use of machine learning algorithms, and the integration of advanced sensors for enhanced data collection.

How can I apply for admission to DCS Program

In the ever-evolving landscape of technology, pursuing a Distributed Control Systems (DCS) program can open doors to exciting career opportunities in the field of industrial automation. If you're eager to delve into the world of DCS and are wondering how to apply for admission to a DCS program, here's a step-by-step guide to help you navigate the application process.

Research the DCS Programs

Explore Program Options

Before applying, take the time to research and explore different DCS programs. Look for accredited institutions that offer comprehensive curricula aligned with your career goals. Consider factors such as program duration, coursework, and faculty expertise.

Check Admission Requirements

Each DCS program may have specific admission requirements. Check the program's official website or contact the admissions office to understand prerequisites such as educational qualifications, relevant work experience, and any standardized test scores needed.

Prepare Application Materials

Academic Transcripts

Gather your academic transcripts from previous educational institutions. Most DCS programs require transcripts as part of the application process.

Letters of Recommendation

Secure letters of recommendation from professors, employers, or professionals who can attest to your academic abilities and potential in the field of DCS.

Resume or Curriculum Vitae (CV)

Prepare a comprehensive resume or CV highlighting your educational background, work experience, relevant skills, and any certifications related to industrial automation or control systems.

Statement of Purpose

Write a compelling statement of purpose that outlines your motivation for pursuing a DCS program, your career goals, and how the program aligns with your aspirations.

Submitting the Application

Online Application Form

Complete the online application form provided by the institution. Ensure that you provide accurate and up-to-date information.

Application Fee

Pay the application fee, if applicable. Some institutions may require a fee to process your application. Check the program's guidelines for details on the payment process.

Entrance Exams

Standardized Tests

If required, schedule and take any standardized tests specified by the DCS program. Common tests may include the GRE (Graduate Record Examination) or other relevant exams.

Prepare for Interviews

Be prepared for potential interviews as part of the admission process. Some programs may conduct interviews to assess your suitability for the DCS program.

Financial Aid and Scholarships

Explore Financial Aid Options

Research available financial aid options, scholarships, or grants offered by the institution or external organizations. Prepare necessary documents for financial aid applications.

Submit FAFSA (Free Application for Federal Student Aid)

If you are a U.S. citizen or eligible noncitizen, submit the FAFSA to determine your eligibility for federal student aid programs.

Await Admission Decision

Check Application Status

Regularly check the application status through the institution's online portal. Be proactive in addressing any additional documentation or information requested by the admissions office.

Prepare for Enrollment

Once accepted, follow the instructions provided for enrollment. Submit any required documents, pay enrollment fees, and prepare for the start of the DCS program.

What is the eligibility for DCS

Eligibility for DCS Program: A Comprehensive Guide

If you're intrigued by the world of Distributed Control Systems (DCS) and considering pursuing a DCS program, it's essential to understand the eligibility criteria for admission. Eligibility requirements can vary among institutions, but this guide provides a general overview to help you determine if you meet the typical prerequisites for entering a DCS program.

Educational Qualifications

Bachelor's Degree in a Relevant Field

Most DCS programs require applicants to hold a bachelor's degree in a relevant field such as electrical engineering, mechanical engineering, computer science, or a related discipline. Ensure that your degree aligns with the program's academic prerequisites.

Minimum GPA Requirements

In addition to a relevant bachelor's degree, institutions often specify a minimum Grade Point Average (GPA) for eligibility. Commonly, a GPA of 3.0 or higher on a 4.0 scale is preferred.

Work Experience

Professional Experience (Optional)

While not always mandatory, having relevant work experience in industrial automation, control systems, or a related field can strengthen your application. Some programs may consider professional experience as part of the eligibility criteria.

Prerequisite Courses

Completion of Required Courses

Certain DCS programs may have specific prerequisite courses that applicants must have completed during their undergraduate studies. These prerequisites typically cover topics such as control systems, automation, and programming.

Standardized Test Scores

GRE (Graduate Record Examination)

Many DCS programs require applicants to submit GRE scores. Check the specific requirements of the program you're interested in and prepare accordingly for the GRE if it's part of the eligibility criteria.

Language Proficiency

English Language Proficiency

For non-native English speakers, demonstrating proficiency in English is crucial. Most institutions accept standardized English language proficiency tests such as the TOEFL (Test of English as a Foreign Language) or IELTS (International English Language Testing System).

Letters of Recommendation

Professional Recommendations

Typically, DCS programs ask for letters of recommendation from professors, employers, or professionals who can vouch for your academic capabilities and potential in the field.

Statement of Purpose

Motivation for DCS Program

Craft a compelling statement of purpose that outlines your motivation for pursuing a DCS program, your career goals, and how the program aligns with your aspirations. This document is often a key component of the application process.

How long does it takes to complete a DCS program

Embarking on a journey into the realm of Distributed Control Systems (DCS) through a specialized program is an exciting prospect. However, understanding the time commitment required is essential for effective planning. The duration of a DCS program can vary based on factors such as the level of the program, the institution's structure, and the specific curriculum. Let's explore what you can generally expect when it comes to the timeline for completing a DCS program.

Types of DCS Programs

Undergraduate Programs

For those pursuing a bachelor's degree in DCS or a related field, the typical duration is four years. This timeframe includes completing general education requirements, foundational coursework, and specialized DCS courses.

Master's Programs

Master's programs in DCS are often designed to be completed in two years of full-time study. However, some institutions may offer accelerated options, allowing students to finish within 12 to 18 months.

Ph.D. Programs

Doctoral programs in DCS are more research-intensive and can take approximately four to six years to complete. The duration may vary based on the research focus, dissertation development, and individual progress.

Program Structure

Semester vs. Quarter System

The program structure, whether based on a semester or quarter system, can influence the overall duration. Semester-based programs typically have two main terms per academic year, while quarter-based programs may have three.

Full-time vs. Part-time Options

Many institutions offer both full-time and part-time enrollment options. Full-time students generally complete their programs more quickly, while part-time students may extend the duration to accommodate work or other commitments.

Internship or Co-op Components

Integrated Work Experience

Some DCS programs include mandatory internships or co-op experiences, providing students with hands-on industry exposure. While these experiences enhance practical skills, they can extend the overall program duration.

Thesis or Capstone Projects

Research and Project Components

Master's and Ph.D. programs often include a thesis or capstone project requirement. The time needed to complete these research components can impact the overall duration of the program.

Flexibility and Accelerated Options

Flexible Scheduling

Certain programs offer flexibility in scheduling, allowing students to take courses at their own pace. This flexibility can influence the time required for program completion.

Accelerated Programs

Accelerated DCS programs condense coursework and requirements, enabling students to graduate in a shorter timeframe. These programs are often intensive and may include summer sessions.

What are potential career opportunities after DCS

Unlocking Career Opportunities After Completing a DCS Program

Completing a Distributed Control Systems (DCS) program opens doors to a dynamic array of career opportunities in the realm of industrial automation. The skills and knowledge acquired during the program equip graduates for roles that are crucial in diverse industries. Let's explore some potential career paths that await individuals with a background in DCS.

Control Systems Engineer

Responsibilities

Control Systems Engineers design, implement, and maintain control systems, including DCS, to ensure efficient and optimized industrial processes. They play a key role in enhancing automation and control strategies within various industries.

Industries

Control Systems Engineers are in demand across industries such as manufacturing, energy, petrochemicals, and pharmaceuticals.

Process Automation Specialist

Responsibilities

Process Automation Specialists focus on optimizing and automating industrial processes. They leverage DCS to enhance efficiency, reduce manual intervention, and improve overall production outcomes.

Industries

This role is prominent in industries like chemical manufacturing, food processing, and power generation.

DCS Programmer

Responsibilities

DCS Programmers develop and implement the software and code necessary for the operation of Distributed Control Systems. They ensure seamless communication between various components of the system.

Industries

DCS Programmers find opportunities in industries ranging from automotive manufacturing to water treatment plants.

Instrumentation Engineer

Responsibilities

Instrumentation Engineers focus on the design and maintenance of control instruments and systems. They integrate DCS components to enhance precision and accuracy in measurement and control.

Industries

Instrumentation Engineers are vital in industries such as oil and gas, aerospace, and utilities.

Industrial Automation Consultant

Responsibilities

Industrial Automation Consultants provide expertise in implementing automation solutions, including DCS. They assess industrial processes, recommend improvements, and guide organizations in adopting advanced control systems.

Industries

Consultants may work with a variety of industries, offering their insights to enhance overall efficiency.

System Integration Engineer

Responsibilities

System Integration Engineers specialize in integrating DCS with other systems within an organization. They ensure seamless communication and interoperability between different technologies.

Industries

This role is critical in industries where multiple systems need to work cohesively, such as smart manufacturing and integrated supply chain operations.

Research and Development in Automation

Responsibilities

Professionals with a DCS background can contribute to research and development projects focused on advancing automation technologies. This may involve creating innovative solutions or improving existing DCS functionalities.

Industries

Research opportunities exist in academia, private research institutions, and industrial research and development departments.

Syllabus of DCS

Semester 1: Foundations of Industrial Automation

Course 1: Introduction to Industrial Automation

Overview of industrial automation

Historical development and milestones

Basics of control systems

Course 2: Fundamentals of Electrical Engineering

Basic electrical principles

Circuit analysis

Introduction to power systems

Course 3: Programming Basics

Introduction to programming languages

Basics of logic programming

Application of programming in industrial automation

Course 4: Mathematics for Control Systems

Linear algebra and matrices

Differential equations

Laplace transforms

Semester 2: Control Systems Basics

Course 1: Control System Components

Sensors and actuators

Signal conditioning

Transmitters and controllers

Course 2: Instrumentation and Measurement

Principles of measurement

Sensors and transducers

Calibration techniques

Course 3: Programmable Logic Controllers (PLCs)

Introduction to PLCs

Programming and interfacing

PLC applications in industrial control

Course 4: Digital Electronics

Binary systems and logic gates

Flip-flops and sequential circuits

Digital signal processing

Semester 3: Distributed Control Systems (DCS)

Course 1: Introduction to DCS

Evolution and significance of DCS

Components and architecture of DCS

Communication protocols in DCS

Course 2: DCS Programming and Configuration

Programming languages for DCS

Configuration of DCS components

Human-Machine Interface (HMI) design

Course 3: DCS Applications in Industries

Case studies of DCS implementation

DCS in manufacturing, energy, and process industries

Real-time monitoring and control

Course 4: Cybersecurity in DCS

Cyber threats and vulnerabilities

Security measures for DCS

Best practices in DCS cybersecurity

Semester 4: Advanced DCS Topics

Course 1: Advanced Control Strategies

Model-based control

Adaptive control

Predictive control

Course 2: System Integration and Networking

Integration of DCS with other systems

Networking principles for DCS

Troubleshooting and maintenance

Course 3: DCS Project Work

Hands-on DCS project

Integration of theoretical knowledge into practical applications

Project presentation and evaluation

Course 4: Industry Internship

Hands-on experience in an industrial setting

Exposure to real-world DCS applications

Internship report and evaluation

Semester 5: Electives and Specializations

Course 1: Industrial Robotics

Introduction to robotics

Robotic programming and control

Applications of robotics in automation

Course 2: Advanced Process Control

Process modeling and simulation

Advanced control strategies for complex processes

Optimization techniques in process control

Semester 6: Research and Dissertation

Course 1: Research Methodology

Research design and methodology

Data collection and analysis

Ethical considerations in research

Course 2: Dissertation Work

Independent research project

Dissertation writing and presentation

Peer review and evaluation

Internship opportunities after completing DCS

Completing a Distributed Control Systems (DCS) program not only equips you with theoretical knowledge but also provides a solid foundation for practical application in real-world scenarios. Securing an internship after completing a DCS program is an excellent way to gain hands-on experience, apply theoretical concepts, and enhance your employability. Let's explore the various internship opportunities that await individuals with a DCS background.

Control Systems Engineer Intern

Responsibilities

Assist in designing and implementing control systems.

Work with senior engineers on system integration projects.

Troubleshoot and debug control systems components.

Industries

Manufacturing

Energy

Aerospace

Process Automation Intern

Responsibilities

Collaborate on projects aimed at process optimization.

Assist in implementing automation solutions using DCS.

Gain hands-on experience with DCS programming and configuration.

Industries

Chemical processing

Food and beverage

Power generation

DCS Programmer Intern

Responsibilities

Work on coding and programming tasks for DCS systems.

Assist in software development and testing.

Collaborate with the programming team on system enhancements.

Industries

Automotive manufacturing

Water treatment

Pharmaceutical

Instrumentation Engineering Intern

Responsibilities

Learn about instrumentation and measurement devices.

Assist in calibrating sensors and transducers.

Work on the installation and maintenance of control instruments.

Industries

Oil and gas

Utilities

Renewable energy

Industrial Automation Consultant Intern

Responsibilities

Shadow experienced consultants on client engagements.

Participate in assessing and optimizing industrial processes.

Assist in recommending automation solutions, including DCS.

Industries

Consulting firms

Engineering services

System integration companies

System Integration Engineer Intern

Responsibilities

Gain exposure to integrating DCS with other systems.

Assist in troubleshooting and maintaining integrated systems.

Collaborate on projects involving interoperability of different technologies.

Industries

Smart manufacturing

Integrated supply chain operations

Building automation

Research Assistant in Automation Intern

Responsibilities

Assist in research projects focused on advancing automation technologies.

Contribute to the development of innovative solutions.

Gain experience in data analysis and experimentation.

Industries

Research institutions

Academic laboratories

Industrial research and development departments

DCS Support and Maintenance Intern

Responsibilities

Work on routine maintenance tasks for DCS components.

Assist in diagnosing and resolving issues in control systems.

Gain practical experience in system upgrades and enhancements.

Industries

Petrochemical

Manufacturing facilities

Energy utilities

Cybersecurity Analyst Intern in DCS

Responsibilities

Learn about cybersecurity threats and vulnerabilities in DCS.

Assist in implementing security measures and best practices.

Work on projects aimed at securing DCS systems.

Industries

Cybersecurity firms

Industrial cybersecurity departments

Government agencies

Scholarship and grants for DCS

Navigating Scholarship and Grant Opportunities for DCS Programs

Pursuing a Distributed Control Systems (DCS) program can be a rewarding but financial commitment. Fortunately, various scholarship and grant opportunities exist to alleviate the financial burden for aspiring individuals. Here's a guide to navigating these opportunities and potentially securing financial assistance for your DCS education.

Institutional Scholarships

Description

Many educational institutions offering DCS programs provide merit-based scholarships for outstanding academic performance. These scholarships may cover partial or full tuition costs.

Application Process

Check with the admissions or financial aid office for available institutional scholarships.

Review eligibility criteria and application deadlines.

Submit required documents, such as transcripts, letters of recommendation, and a personal statement.

Industry-Specific Scholarships

Description

Several industries that heavily rely on DCS, such as manufacturing and energy, offer scholarships to support students pursuing education in control systems and automation.

Application Process

Explore industry associations, companies, or foundations associated with industrial automation.

Check their websites for scholarship opportunities and application guidelines.

Submit required documents showcasing academic achievements and interest in the field.

Professional Organizations and Associations

Description

Professional organizations related to control systems and automation often provide scholarships for students entering the field. These organizations aim to support the next generation of professionals.

Application Process

Join relevant professional organizations, such as the International Society of Automation (ISA) or the Institute of Electrical and Electronics Engineers (IEEE).

Explore scholarship opportunities listed on their websites.

Follow application instructions and deadlines.

Government Grants and Scholarships

Description

Government agencies may offer grants and scholarships for students pursuing degrees in STEM fields, including control systems and automation.

Application Process

Research government programs supporting STEM education.

Check eligibility criteria and application requirements.

Submit applications through the designated channels.

Corporate Sponsorships

Description

Many corporations actively invest in supporting the education of students entering fields critical to their industry, such as industrial automation.

Application Process

Explore corporate websites for information on education sponsorships or scholarships.

Review eligibility criteria and application procedures.

Submit applications along with required documentation.

Diversity and Inclusion Scholarships

Description

Some scholarships specifically target underrepresented groups in STEM fields, aiming to promote diversity and inclusion in the industry.

Application Process

Look for scholarships emphasizing diversity and inclusion in STEM.

Check eligibility criteria and ensure alignment with your background.

Submit applications with relevant supporting documents.

Nonprofit Organizations

Description

Nonprofit organizations focused on education and STEM initiatives may offer scholarships to support students pursuing DCS education.

Application Process

Research nonprofit organizations with a commitment to STEM education.

Check for scholarship opportunities and application guidelines.

Submit applications with necessary documentation.

Conclusion

Navigating scholarship and grant opportunities for a DCS program requires thorough research, careful planning, and timely applications. Start by exploring options at the institutional level, then broaden your search to industries, professional organizations, government programs, corporate sponsors, diversity-focused scholarships, and nonprofit organizations. Keep in mind deadlines, eligibility criteria, and the specific requirements of each opportunity. By leveraging these opportunities, you can make your DCS education more accessible and pave the way for a successful career in industrial automation.

FAQs

Q1: What is a Distributed Control System (DCS)?

A1: A Distributed Control System (DCS) is a computerized control system used to monitor and manage industrial processes, ensuring optimal efficiency and safety. It consists of multiple control units distributed throughout a facility, communicating with each other to control various processes.

Q2: How does a DCS differ from a PLC (Programmable Logic Controller)?

A2: While both DCS and PLC are used in industrial automation, the key difference lies in their scope. DCS is designed for complex, large-scale processes involving multiple control units, offering enhanced communication capabilities. PLCs are more suitable for smaller, standalone tasks.

Q3: What industries commonly use DCS?

A3: DCS is widely used in industries such as manufacturing, energy, petrochemicals, pharmaceuticals, and water treatment. Its applications range from controlling production lines to managing complex chemical processes.

Q4: What are the core components of a DCS?

A4: The core components include:

Controller Units: Processors that execute control algorithms.

Input/Output Modules: Interface between the control system and field devices.

Human-Machine Interface (HMI): Graphical interface for operators to monitor and control processes.

Communication Network: Connects all components for seamless data exchange.

Q5: How does cybersecurity apply to DCS?

A5: With the increasing connectivity of industrial systems, DCS cybersecurity is crucial. Measures include firewalls, access controls, encryption, and regular security audits to protect against cyber threats and ensure the integrity of control systems.

Q6: Can I pursue a career in DCS with a background in electrical engineering?

A6: Absolutely. A background in electrical engineering provides a solid foundation for understanding control systems. Additional training or a specialized DCS program can further enhance your skills for a career in DCS.

Q7: What are the advantages of using DCS in industrial processes?

A7: DCS offers:

Centralized Control: Efficient management of multiple processes.

Real-time Monitoring: Continuous monitoring for rapid decision-making.

Flexibility: Easy modification of control strategies.

Improved Safety: Enhanced control and safety features.

Q8: Are there certifications for DCS professionals?

A8: Yes, several certifications, such as Certified Automation Professional (CAP) and DCS-specific certifications, validate expertise in industrial automation and control systems.

Q9: How long does it take to learn DCS programming?

A9: Learning DCS programming can vary based on prior experience and the depth of knowledge sought. Basic proficiency can be achieved in a few months, while mastering advanced features may take longer.

Q10: What is the future outlook for careers in DCS?

A10: The future for DCS careers is promising. As industries continue to embrace automation, the demand for skilled professionals in control systems and DCS is expected to grow, providing ample career opportunities.